Over the past few years, bottling groups have made considerable progress:

- empty bottles are rinsed and drained

- corking is done in vacuum to restrict air entering the bottle

- inert gas is used while the wine is being drawn

- accumulation tables are now made longer to guarantee the dilation of the cork before laying the bottles down.

The importance of controlling oxygen during bottling:

Oxygen is essential in wine-making, but an excessive and poorly controlled input of oxygen during this procedure could lead to making the wine develop far too early. There are now various systems to blow inert gas (nitrogen, argon,…) into the bottle before or after bottling.

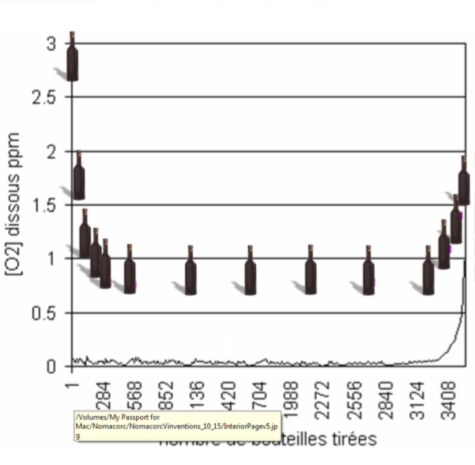

Even so, bottles at the beginning and end of the bottling line are always more exposed to the risk of oxygen entering.

The importance of corking:

Cork quality is the other decisive factor in conserving a wine’s quality and the consistency of its development.

Cork is historically the traditional natural corking product. It possesses indisputable elasticity and permeability to oxygen, which enable a wine to develop gradually.

However, once infected, cork can produce some unpleasant smells and tastes (known as a corky taste). This problem can be attributed to a compound called TCA (Trichloroanisole). In high concentration, this defect can be picked up by any wine taster: it’s a musty, earthy smell.

This defect is trickier to perceive when concentration of TCA is barely recognisable, but wine quality is diminished, nevertheless: aromas are dull and the wine is drier on the palate.

These observations have been pointed out by wine industry professionals and consumers for several years now. Cork producers are focusing on the following areas of research and development:

- guarantee corks which have no risk of giving wine a corky taste

- ensure consistent permeability for each batch of corks